What is the Responsibility of an Asset Manager?

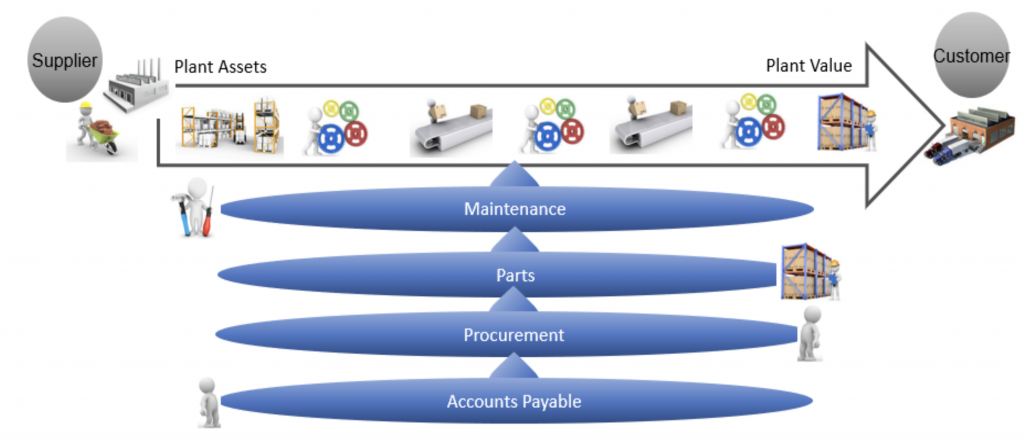

There have been many views shared about the value of an asset in an asset intensive organization but perhaps the simplest view is to accept that each asset fundamentally was acquired to help produce ‘value’ in the enterprise.

Operations typically would be expected to leverage the enterprise assets to produce a service or product that can be externally saleable. When the service or product is sold, the processes – and related asset(s) – directly contribute to the enterprise’s financial return. In short: every asset in a production process drives ‘value’ in the enterprise’s supply chain to their clients.

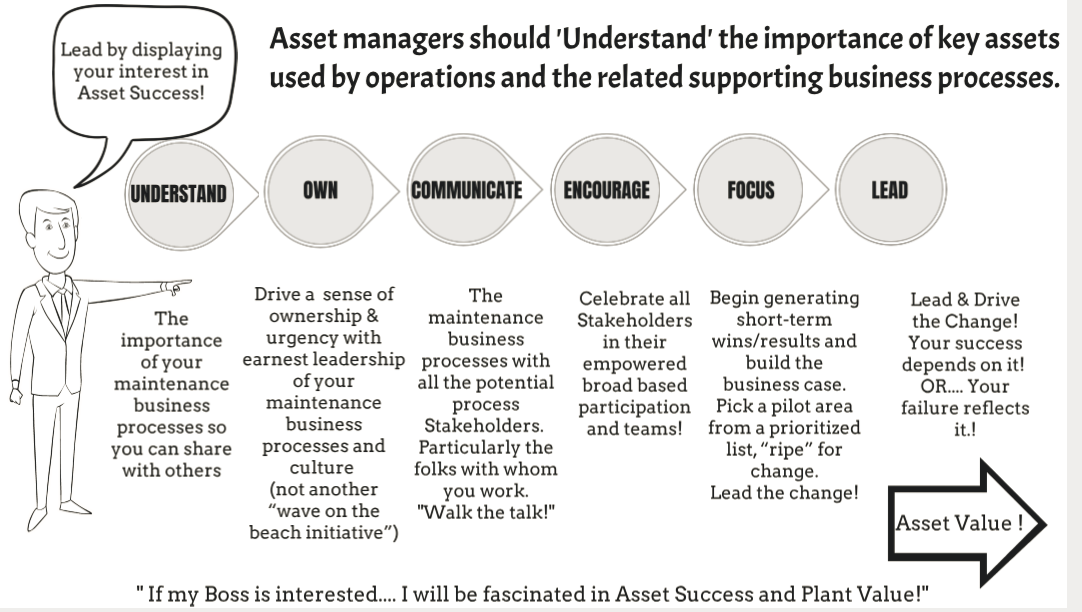

The responsibility of the Asset Manager is to ‘Understand’ the importance of a specific asset used by operations and its related maintenance business processes. The Asset Manager should have a way to share with all the potential stakeholders that may have an impact or influence on the tolerable risks relating to that key asset’s reliability.

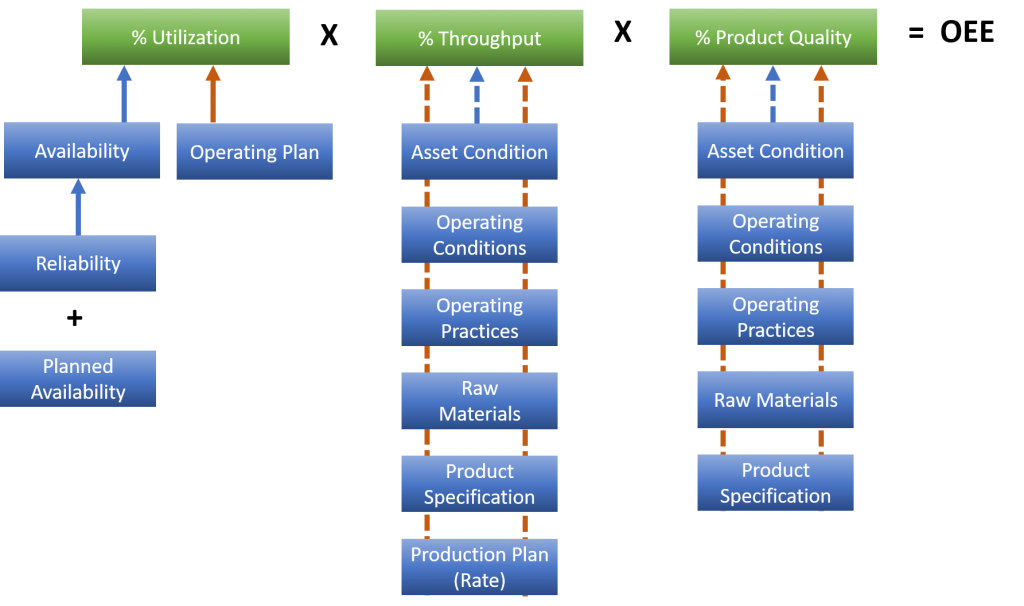

An asset’s reliability will impact its availability and the degree in which the asset can be available for productive utilization.

Understanding the asset health (condition and probability of failure) along with operational elements including operation conditions, practices, specifications, production plans and raw material access ability will influence the potential process/asset throughput and the quality of that process/asset throughput.

With a simple focus on asset availability, throughput and quality of throughput both the asset Manager and the Operations team can measure a perspective (baseline) of Overall Equipment Effectiveness for a production line or (if the data is available) a specific asset.

The Asset Manager is always expected to respond to asset functional failures (firefight) and ideally set up the maintenance team culture to be able to address these asset deficiencies in a timely and cost-effective manner.

The optimal Asset Management organizational will – as a matter of culture- tenaciously identify asset priorities, predict potential failures before they impact the critical processes and have in place an asset failure mitigation tactic in place to minimize asset functional failure business impacts. To get to this higher level of optimal asset management operating culture – the Asset Manager must create a genuine sense of urgency for the need to ensure that key assets drive the business value – in support of why the enterprise exists – to drive operational value.

Such a focus and earnest leadership of asset management and maintenance business processes is not a “program of the month.” It is the leadership and communication of culture change and in most cases higher levels of operating standards.

The Asset Manager will be seen:

- to communicate the maintenance business processes and standards with the folks with whom they work (walk the talk);

- to encourage all plant personnel to participate in the total success of the enterprise by viewing asset with broad based action (teams);

- to focus on key processes, generating short-term wins/results and building a business case (pick a pilot area from a prioritized list, “ripe” for change);

- to lead the asset reliability success story because the success of the enterprise depends on it! (Or their lack of leadership and focus and failure reflects it.)

The typical Maintenance craft will want to understand that they are ‘making a difference’ in their business. They will understand the value of an efficient and effective maintenance culture and will want to contribute to a well lead Asset Management program in their enterprise.

The Asset Manager should also recognize that teaming with Operations and the many stakeholders that may influence a leading Asset Management program go beyond just the folks in Maintenance and Operations.

Potential enterprise stakeholders that will have an influence on the success of an optimal Asset Management Program and in turn the bottom line of a service or production organization can include: Vendors, Design Engineering, Operations, Maintenance (Craft, Planners, Schedulers, supervisors, Leadership), Parts Planning and Warehousing, Procurement, IT, HR, Finance and Legal.

As well: IT and data analytics particularly can play an important stakeholder support role in automating processes, replenishment and analytics in support of optimal Maintenance management.

The Asset Manager should be the champion of asset value and of the asset life-cycle. This is no small task. The pursuit of asset optimization and driving value to the enterprise – when done well – is a very rewarding assignment.