Primary Asset Maintenance Systems can be supported by ERPs and EAM solutions that provide data and transaction management for asset hierarchies and maintenance history. Ideally, the system will have direct integration with their spare parts management solution, a Customer Management system (if appropriate), a Supplier Management solution, and the appropriate service level agreement solutions.

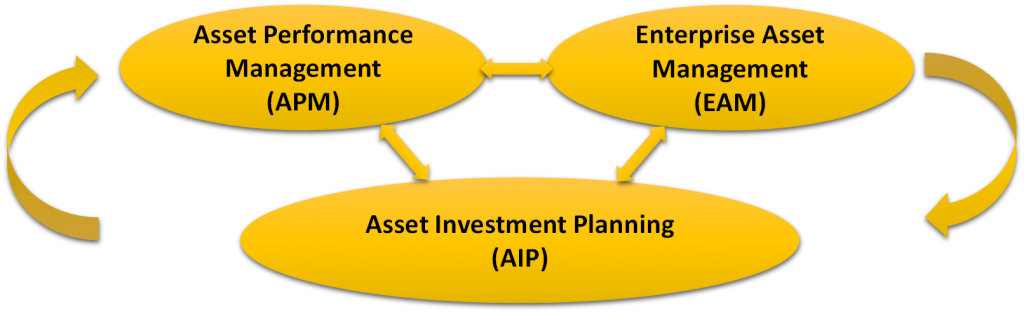

Complimenting EAM solutions:

- Asset Life-cycle planning solutions (including Asset Investment Planning – AIP) and

- Asset Performance Management (APM) solutions and analysis

A high-level list of generic EAM Functions and categories

- Asset Management

- Work Management

- Parts Inventory Management

- Procurement

- Vendor Management

- Service Level Management

- Financial Management

- Customer Management

- Reporting

- Analytics

- Asset Reliability

- Workforce Management

- Health, Safety & Environment Management

- Calibration

- Rotating Asset Management

- Mobile Support

- Industry-specific Solutions

- EAM Systems Administration

- User Help Functions

Refer to the “Asset Data Management and Technology Support” for more insights on this topic

Asset Maintenance – Maintenance Execution

Maintenance execution is all about efficient Planning and Scheduling. When applied well and managed in a system (i.e. EAM solution), the selected maintenance task can be most efficient when a supported maintenance task plan is well documented.

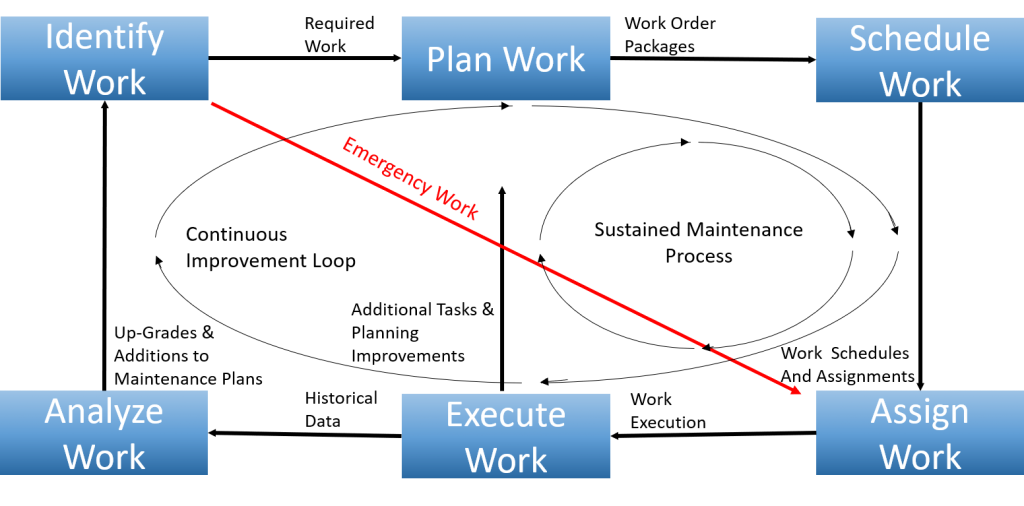

The steps that make up the Planning and Scheduling cycle include: Identifying the work, Planning the work, Scheduling the work, Assigning the work, Executing the work, and Analyzing the effectiveness of the work (plan).

Notwithstanding emergency work will often need to bypass the Planning and Scheduling steps due to the urgent situation.

The training supporting the process and/or the importance of Planning and Scheduling is available. Refer to “The Asset Management Education” section of this website

Asset Maintenance – Maintenance Metrics

Fundamental Maintenance Management metrics may be considered a fairly simple task to put together. Often recommended asset metrics will include measuring: asset availability or reliability and maintenance metrics could include percent of planned versus unplanned maintenance and percent compliance to schedule.

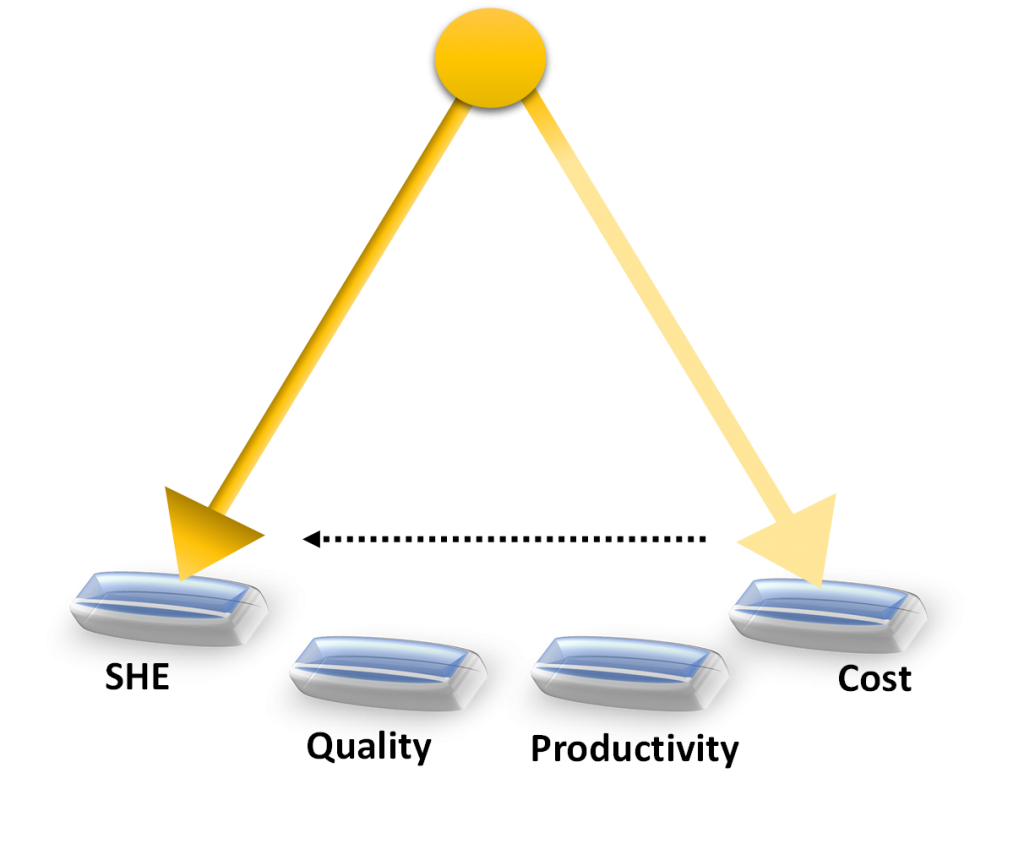

KPI focus can swing from Cost to SHE or in between (SHE = Safety, Health, and Environment)

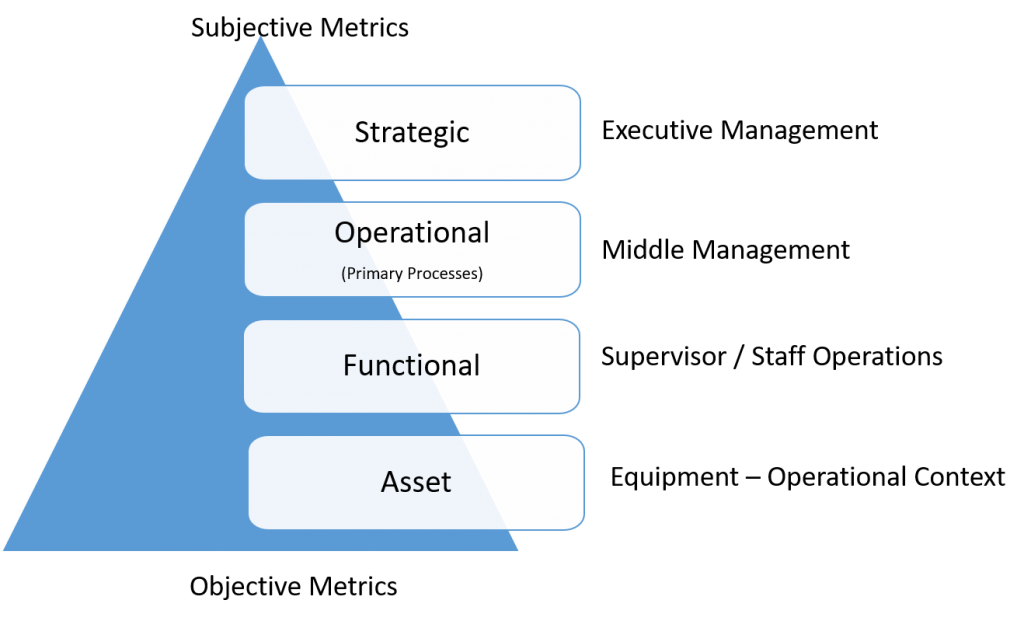

Getting the whole organization on the same page and supporting each level of the business (Strategy, Operational, Functional,) and the priority pendulum of business drivers dynamically is typically a more complex exercise to work through.

Asset Acumen Consulting Inc. helps organizations work through the maze of potential focus areas to help them to identify the needed (and available) asset and maintenance-related metrics and prioritize based on the business strategic and operational dynamic.